Limitless Memory Potential Customers can retailer a lot of processing data thanks to the endless memory capability, maximizing traceability of production procedures.

Sophisticated Engine Factors - Engine areas which include pistons or engine blocks characteristic intricate geometries, which include recesses, holes, and unique styles that can't be quickly attained as a result of turning.

The main distinction between regular and precision CNC machining is accuracy. CNC precision machining tools can run a similar list of Guidelines to obtain tight precision and regularity across batches. This repeatability helps to make sure the production of similar pieces in massive volumes.

CNC Machines may even give logistical assistance once the auction is over. Every person who wins an item can access out to us for issues pertaining to shipping and rigging.

A file is undoubtedly an abrasive surface similar to this one particular which allows machinists to remove modest, imprecise quantities of metallic. Submitting is mixture of grinding and observed tooth reducing utilizing a file. Previous to the event of modern machining products it presented a relatively accurate usually means with the production of compact pieces, especially All those with flat surfaces.

Furthermore, milling excels in dealing with elements which might be tough to turn, which include hardened steels and exotic alloys.

The programming of work cycles is done by entering the identical parameters on the cycle. The sequence of execution of the assorted cycles is often speedily and intuitively improved.

cnc precision machining Enable’s start with what exactly is CNC machining initially. It is actually a pc-managed machining process that immediately eliminates substance based upon uploaded structure and digital Guidance. The automation in tool motion provides tighter tolerance than traditional machining techniques.

Furthermore, plastics are popular in precision prototyping machining as well as the production of industrial parts throughout industries.

The system of CNC drilling involves a rotating drill bit and stationery workpiece. Since the drill little bit penetrates the surface, it cuts and chips away the material within the drilling location to create check here a hole. The drill bits are a similar size as the diameter of the specified gap.

CNC milling is the preferred process for elements with advanced geometries, including All those requiring numerous faces, intricate designs, or detailed capabilities including pockets and slots.

Because of the frequently symmetrical mother nature on the chopping (because the workpiece is transferring), this process is generally used to produce cylindrical and round components, even though it can also be used for making hexagonal areas too.

There are many different types of CNC milling machines that allow for various amounts of complexity inside the chopping course of action. The simplest machines have a tendency to get three axes of movement, but extra advanced types may have five or even more.

Contrary to welding, the perform piece is not really melted. Brazing is comparable to soldering, but happens at temperatures in excessive of 450 °C (842 °File). Brazing has the advantage of making considerably less thermal stresses than welding, and brazed assemblies are typically much more ductile than weldments simply because alloying features can not segregate and precipitate.

Edward Furlong Then & Now!

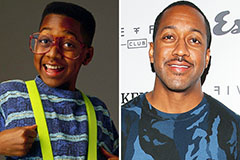

Edward Furlong Then & Now! Jaleel White Then & Now!

Jaleel White Then & Now! Hallie Eisenberg Then & Now!

Hallie Eisenberg Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now! Seth Green Then & Now!

Seth Green Then & Now!